During the hand-press era, the raw material for the production of paper for books was cloth rags – most often linen. Rags were bought in bulk by paper-makers, often sold to them by itinerant rag collectors; rag-and-bone men. The paper-making process began with washing the linen, which was left it in a damp heap to rot. After four or five days, the rotten rags were cut into smaller pieces, and then pounded down to form a pulp, using water-powered hammers. This pounding process was repeated two or three times; with pauses in between to allow for further rotting. By the 18th century the hammers had been replaced by a rotary machine which macerated the rags using knives – a much more efficient method. Invented in Holland, the machine was known as a Hollander.

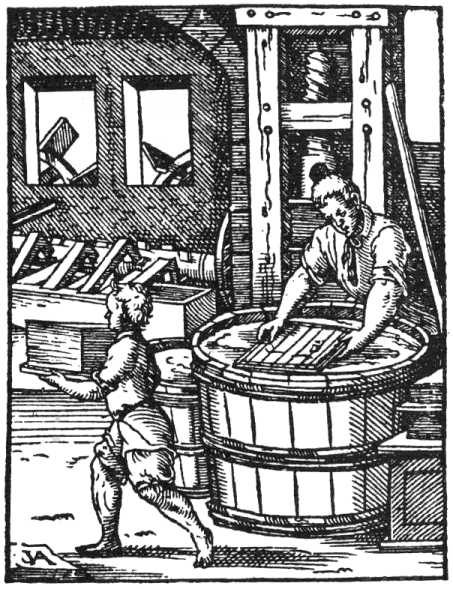

Once the process of breaking-up and rotting down the rags was complete the pulp that remained was put into a vat and watered down to form a concoction resembling a watery porridge. Further stretching the porridge analogy – this mixture was kept warm and stirred occasionally using a paddle.

A close-meshed sieve made of metal wire (the mould) was then dipped into the mixture, before being lifted out with exactly the right amount of pulp in, laid flat, and skillfully manipulated to form a uniform ‘sheet’ of pulp across the mould. The mould was then expertly shaken, first forward and backward, and then side to side, to ensure the fibres crossed in each direction, which helped to strengthen the paper. The sheets were then removed from the mould and sandwiched between layers of felt. The resultant piles of paper interleaved with felt were put under a heavy press to squeeze out excess water before being hung up to dry.

The quality of the paper produced using this method was primarily determined by the quality of the rags used to make it. The best paper was produced from pure white linen; poorer quality paper from materials such as canvas, rope and wool. Linen rags were not readily available in England, where people wore wool rather than linen. This fact, combined with a lack of skilled workmen, meant that most paper used in the English book trade, up until around the middle of the 18th century, was imported from France or Holland.

By the 19th century, the demand for rags to make paper with was outstripping supply, and prices reflected this. This intensified the search for an alternative; which eventually resulted in the majority of paper being made using wood-pulp – and increasingly using machines, rather than by hand – from the middle of the century.

As it happens, a conference, ‘The Paper Trade in Early Modern Europe: Practices, Materials, Networks’ took place in Erlangen, Germany, on the 26th and 27th February. You can read about current research in paper, as presented at the conference, by searching for the Twitter handle #EMpapertrade.

References and further reading:

Gaskell, Philip. A new introduction to bibliography, 1972

Burke, James. From rags to paper, 2013

University of Ilowa. Paper through time: nondestructive analysis of 14th-through-19th century papers (project website).